Lithium-Sulfur Batteries

Technical Content

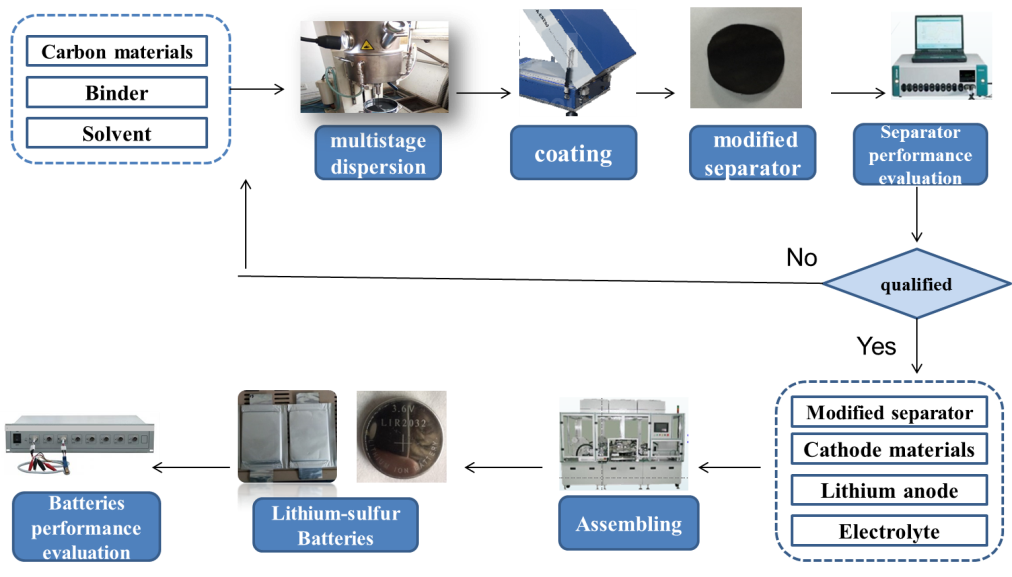

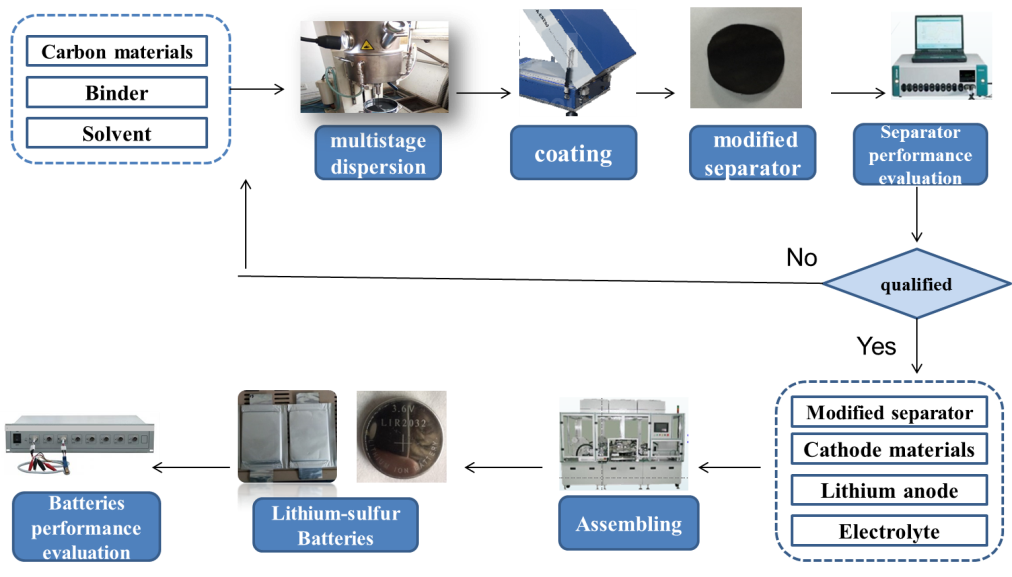

In this project, carbon materials with high specific surface, binder and solvent are well-distributed to fabricate the slurry through a multistage dispersion process. The slurry is then coated on the routine commercial separator, and the modified separator is obtained after drying. The modified separator, cathode materials, lithium anode and electrolyte, are well matched and assembled into high performance lithium-sulfur batteries.

Advantages

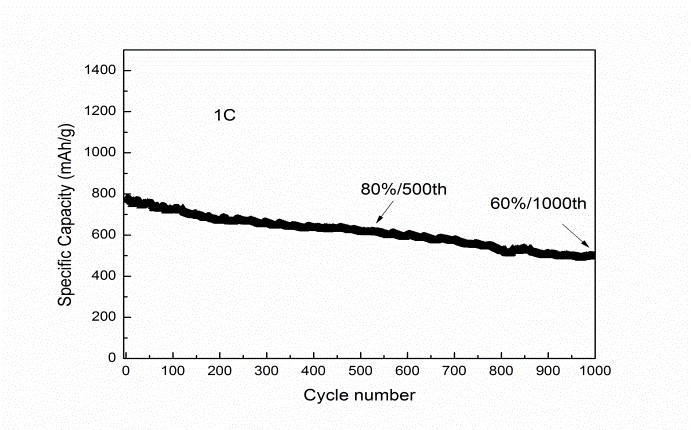

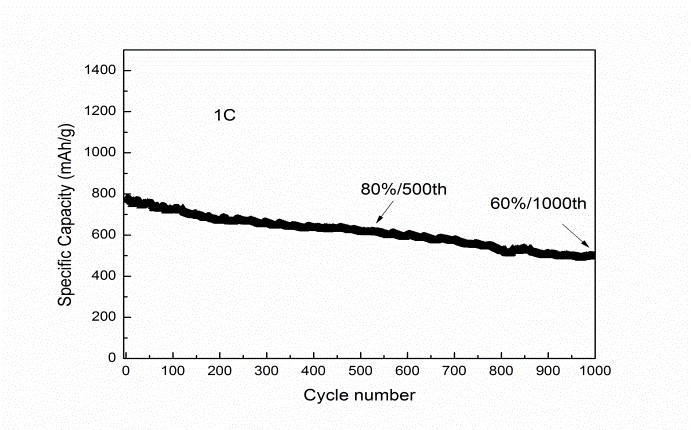

The carbon material modified separator developed in this project effectively inhibits the polysulfide dissolution, promoting the utilization of the sulfur electrode, and hence contributes to the high capacity performance of the lithium-sulfur batteries. The assembled lithium-sulfur batteries exhibits a high discharge specific capacity of 620mAh/g after1000 cycles at 1C, and the capacity retention is up to 80%. Compared with the lithium-sulfur batteries fields, the performance is remarkable.

Technical Index

| Item | Index |

| Cathode Specific Capacity | ≥800 mAh/g, 1C |

| Capacity Retention(%) | ≥80%,1000 times/1C |

| Working Voltage(V) | 1.7~2.8 |

Market Prospects

According to the "lithium-ion batteries industry development white paper (2018)" issued by the Research Institute EVTank and iwei Economic Research Institute, the global lithium batteries shipments reached 143.5Gwh in 2017, in which the shipments of electric vehicle powered lithium-ion batteries reached 58.1Gwh, the energy storage lithium-ion batteries reached 11.0Gwh, and the other traditional lithium-ion batteries shipments reached 74.4Gwh. Based on the continued promising prospects for the development of automotive powered lithium batteries, EVTank predicts that by 2020, the shipments of electric vehicle powered lithium batteries will reach 166.1Gwh, thus driving the global lithium batteries shipments to 279.9Gwh. In the view of the regional market, China has become the most active area of lithium batteries development in the world. The power lithium batteries market has become the biggest engine of the rapid growth of the global lithium batteries market. Based on the high energy density requirement of power batteries, lithium-sulfur batteries have become the research hotspot at present.

In this project, the lithium sulfur batteries with carbon material modified separator have the advantages of high capacity and long cycle life. It has an absolute advantage in the field of energy storage devices in the future, and has broad application prospects in the fields of new energy power batteries, aerospace and national defense.

Technology Maturity

Laboratory research and development.

Cooperation

Cooperative development.

Lithium-sulfur battery coin cell

Lithium-sulfur battery pack.

The cycle performance of lithium-sulfur batteries at 1C

Lithium-Sulfur Batteries

Technical Content

In this project, carbon materials with high specific surface, binder and solvent are well-distributed to fabricate the slurry through a multistage dispersion process. The slurry is then coated on the routine commercial separator, and the modified separator is obtained after drying. The modified separator, cathode materials, lithium anode and electrolyte, are well matched and assembled into high performance lithium-sulfur batteries.

Advantages

The carbon material modified separator developed in this project effectively inhibits the polysulfide dissolution, promoting the utilization of the sulfur electrode, and hence contributes to the high capacity performance of the lithium-sulfur batteries. The assembled lithium-sulfur batteries exhibits a high discharge specific capacity of 620mAh/g after1000 cycles at 1C, and the capacity retention is up to 80%. Compared with the lithium-sulfur batteries fields, the performance is remarkable.

Technical Index

| Item | Index |

| Cathode Specific Capacity | ≥800 mAh/g, 1C |

| Capacity Retention(%) | ≥80%,1000 times/1C |

| Working Voltage(V) | 1.7~2.8 |

Market Prospects

According to the "lithium-ion batteries industry development white paper (2018)" issued by the Research Institute EVTank and iwei Economic Research Institute, the global lithium batteries shipments reached 143.5Gwh in 2017, in which the shipments of electric vehicle powered lithium-ion batteries reached 58.1Gwh, the energy storage lithium-ion batteries reached 11.0Gwh, and the other traditional lithium-ion batteries shipments reached 74.4Gwh. Based on the continued promising prospects for the development of automotive powered lithium batteries, EVTank predicts that by 2020, the shipments of electric vehicle powered lithium batteries will reach 166.1Gwh, thus driving the global lithium batteries shipments to 279.9Gwh. In the view of the regional market, China has become the most active area of lithium batteries development in the world. The power lithium batteries market has become the biggest engine of the rapid growth of the global lithium batteries market. Based on the high energy density requirement of power batteries, lithium-sulfur batteries have become the research hotspot at present.

In this project, the lithium sulfur batteries with carbon material modified separator have the advantages of high capacity and long cycle life. It has an absolute advantage in the field of energy storage devices in the future, and has broad application prospects in the fields of new energy power batteries, aerospace and national defense.

Technology Maturity

Laboratory research and development.

Cooperation

Cooperative development.

Lithium-sulfur battery coin cell

Lithium-sulfur battery pack.

The cycle performance of lithium-sulfur batteries at 1C

CONTACT US

Sales Manager:

0086+18835170493(Miss. Liu)

WeChat:18835170493

Technical support:

0086+13934640625(Miss. Guo)

graphene@sxicc.ac.cn

WeChat:13934640625

Tel/Fax:0086+03514049061

Post Code:030001

Adress:27 South Taoyuan Road, Taiyuan, Shanxi, P.R.China

Website:http://709.sxicc.ac.cn

0351-4049061