Electronic Paste and Printing Electronic

Technical Content

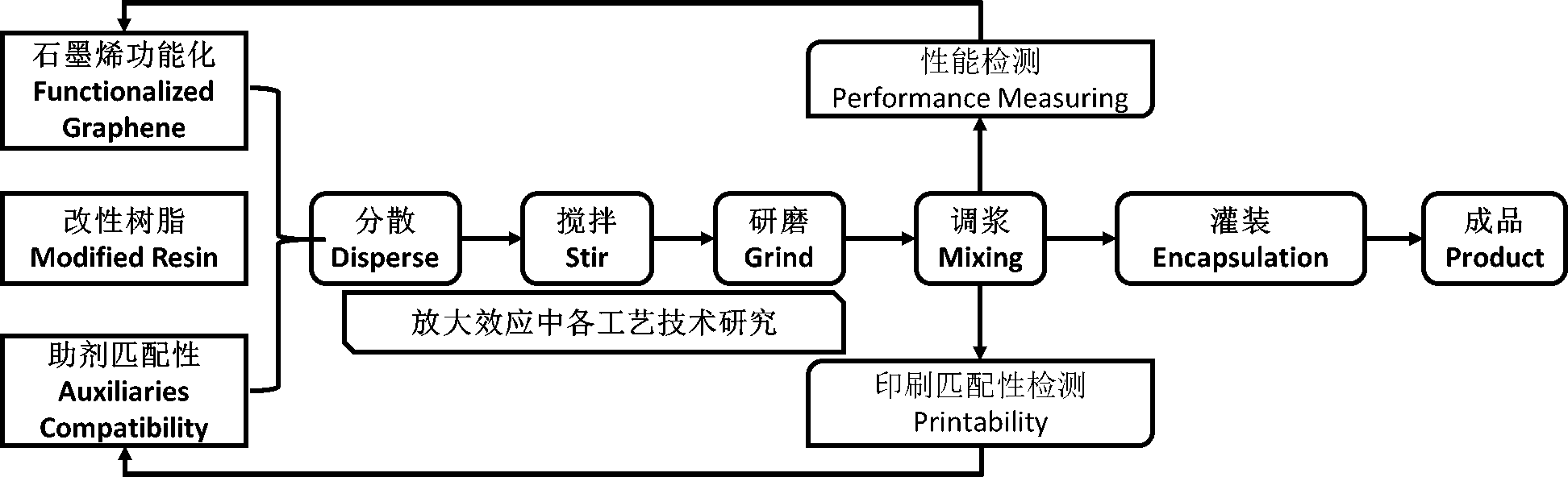

The technology is based on high conductive graphene, using graphene and carbon black as composite conductive filler, modify polymer as binder, and environment-friendly solvent and other additives as supplementary. All the components were nano-dispersed, and the ratio was optimized to successfully produced graphene based electronic paste. With the characterization of exceptionally high conductivity, optimal printing eligibility, mild treat temperature and cheap cost, the graphene based electronic paste is suitable for screen printing, flexography, gravure, offset lithography and paste jet, resulting in a widespread application in flexible circuit board, smart labels, display device, electrode sensor, and infrared radiation heating equipment. Moreover, it can be potentially used in inorganic solar cell, printing battery and supercapacitor.

Advantages

Graphene/carbon fiber is used as composite conductive filler to form an efficient conductive "bridge" in different dimensions, which helps to improve the conductivity of conductive phase (conductive functional unit and conductive assistant). Low resistance polyurethane, fluorocarbonate resin and conductive polymer are initially used to modify the composite binder, which greatly improves electrical conductivity of the binder. The prepared graphene-based conductive ink has the advantages of good printing performance, mild curing conditions and low cost, as its square resistance is less than 0.05Ω/□ and adhesion can reach over 98%.

Technical Index

| Items | Index |

| Solid Content(wt%) | 10-50 |

| Viscosity(mPa?s) | 30000±4500 |

| Square Resistance(Ω/□,25.4μm) | <1 |

| Pencil Rigidity(grade) | >2H |

| Drying Time(min,120 oC) | 30 |

| Adhesion | 100/100 |

Intellectual Properties

Two authorized patents(ZL201510372497.4, ZL201610330047.3).

Market Prospects

According to the research from Ditches, the global market of electrical conductive printing paste for flexible electronics was $ 300 billion in 2026. After the completion of the project, the cost of graphene will reduce to ¥ 100 thousand per ton, and the price ranges from 300 thousand to 500 thousand per ton. The annual profit will reach to ¥ 20 million. Therefore, the investment could be recouped within 2.3 years.

Technology Maturity

Laboratory research and development.

Cooperation

Cooperation development.

The macroscopic image of graphene based electronic paste.

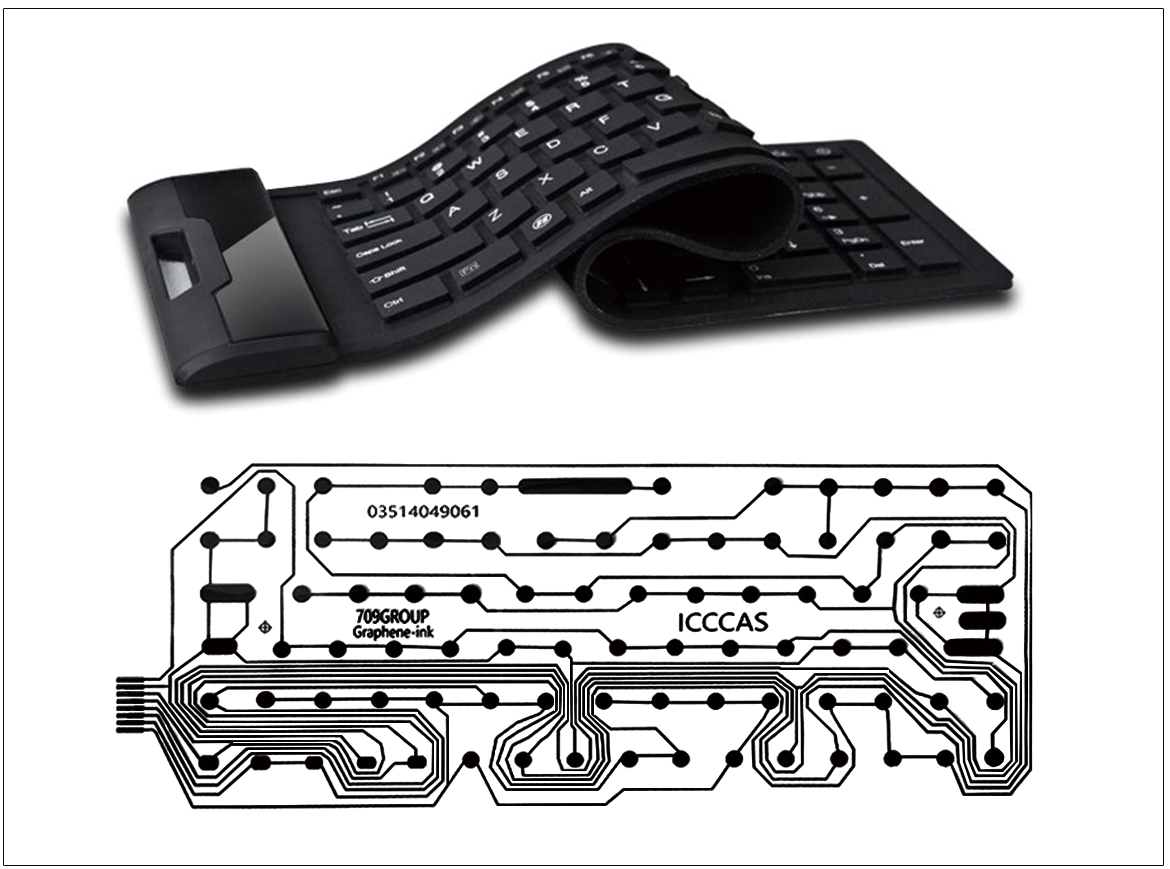

Printed flexible circuit.

Electronic Paste and Printing Electronic

Technical Content

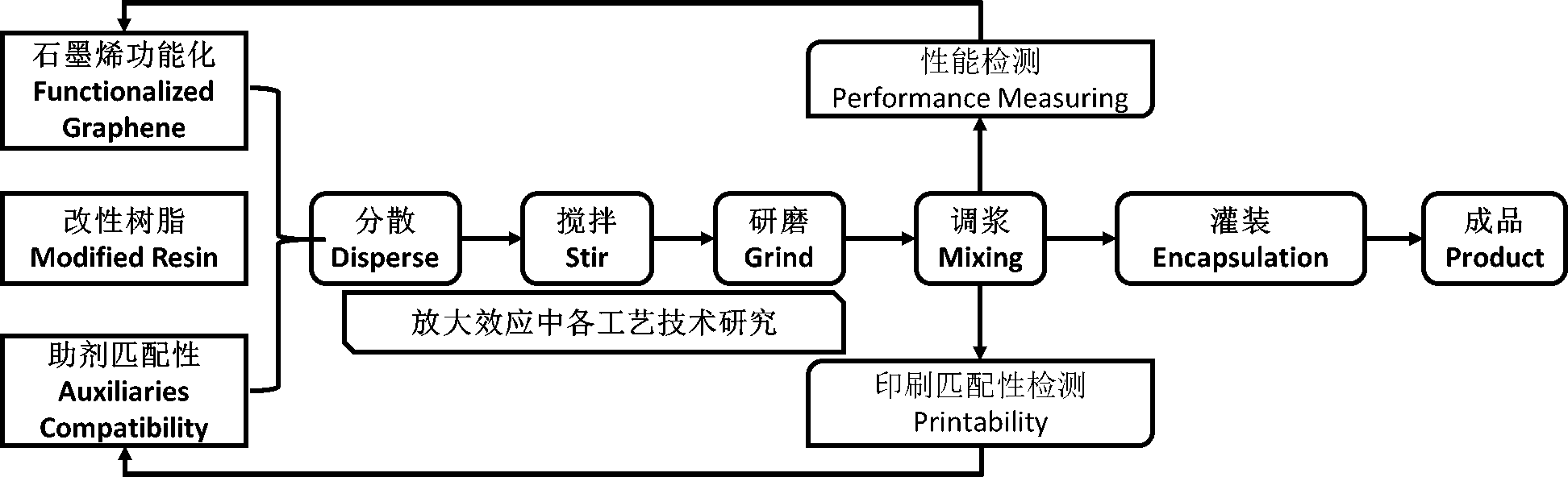

The technology is based on high conductive graphene, using graphene and carbon black as composite conductive filler, modify polymer as binder, and environment-friendly solvent and other additives as supplementary. All the components were nano-dispersed, and the ratio was optimized to successfully produced graphene based electronic paste. With the characterization of exceptionally high conductivity, optimal printing eligibility, mild treat temperature and cheap cost, the graphene based electronic paste is suitable for screen printing, flexography, gravure, offset lithography and paste jet, resulting in a widespread application in flexible circuit board, smart labels, display device, electrode sensor, and infrared radiation heating equipment. Moreover, it can be potentially used in inorganic solar cell, printing battery and supercapacitor.

Advantages

Graphene/carbon fiber is used as composite conductive filler to form an efficient conductive "bridge" in different dimensions, which helps to improve the conductivity of conductive phase (conductive functional unit and conductive assistant). Low resistance polyurethane, fluorocarbonate resin and conductive polymer are initially used to modify the composite binder, which greatly improves electrical conductivity of the binder. The prepared graphene-based conductive ink has the advantages of good printing performance, mild curing conditions and low cost, as its square resistance is less than 0.05Ω/□ and adhesion can reach over 98%.

Technical Index

| Items | Index |

| Solid Content(wt%) | 10-50 |

| Viscosity(mPa?s) | 30000±4500 |

| Square Resistance(Ω/□,25.4μm) | <1 |

| Pencil Rigidity(grade) | >2H |

| Drying Time(min,120 oC) | 30 |

| Adhesion | 100/100 |

Intellectual Properties

Two authorized patents(ZL201510372497.4, ZL201610330047.3).

Market Prospects

According to the research from Ditches, the global market of electrical conductive printing paste for flexible electronics was $ 300 billion in 2026. After the completion of the project, the cost of graphene will reduce to ¥ 100 thousand per ton, and the price ranges from 300 thousand to 500 thousand per ton. The annual profit will reach to ¥ 20 million. Therefore, the investment could be recouped within 2.3 years.

Technology Maturity

Laboratory research and development.

Cooperation

Cooperation development.

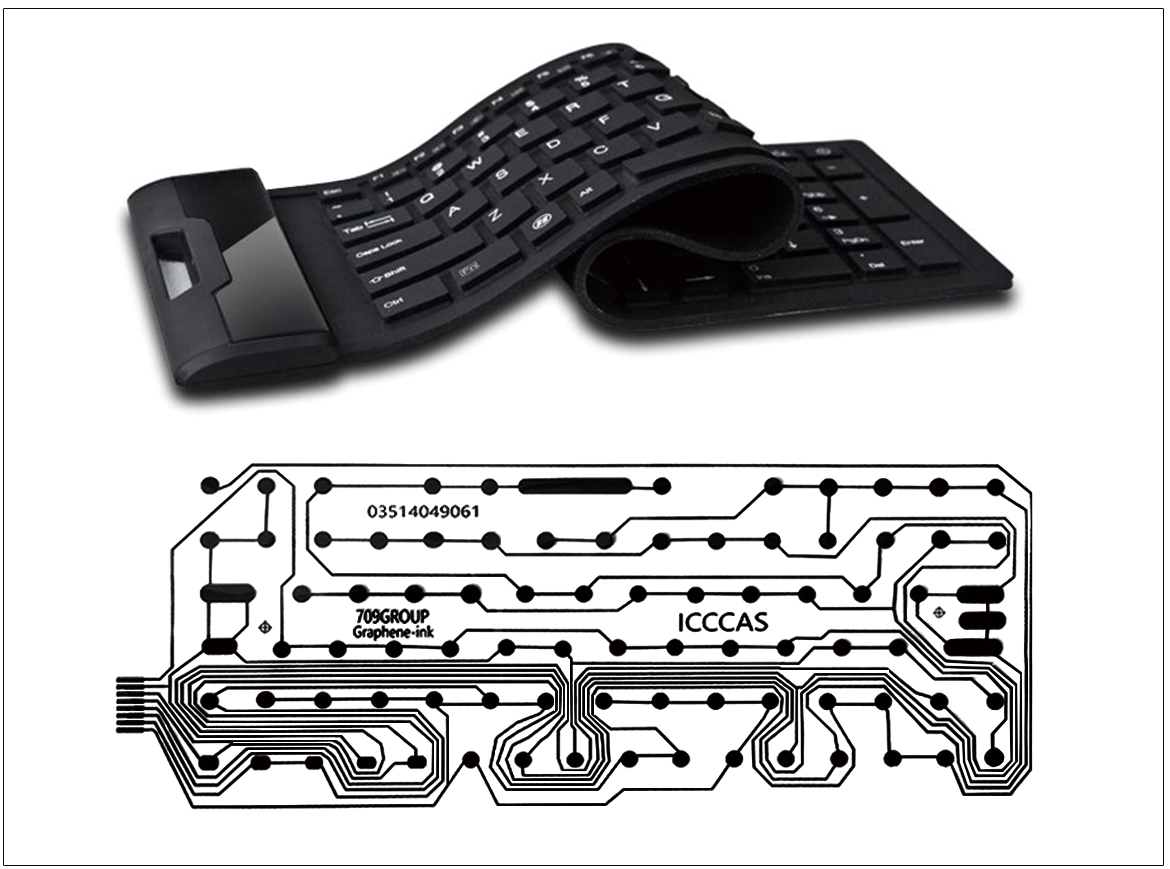

The macroscopic image of graphene based electronic paste.

Printed flexible circuit.

CONTACT US

Sales Manager:

0086+18835170493(Miss. Liu)

WeChat:18835170493

Technical support:

0086+13934640625(Miss. Guo)

graphene@sxicc.ac.cn

WeChat:13934640625

Tel/Fax:0086+03514049061

Post Code:030001

Adress:27 South Taoyuan Road, Taiyuan, Shanxi, P.R.China

Website:http://709.sxicc.ac.cn

0351-4049061