Infrared Heating Ink

Advantages

Graphene infrared heater can be made by simple coating or printing fabrication process with the advantage of energy-efficient. High aspect ratio and high conductivity of graphene provide the heater with strong infrared radiation, low drive voltage, high efficiency of electricity transforming and uniform heating. The infrared (5-14μm) heating system can not only be used for heating, but also for physical therapy on human bodies.

Technical Index

| Items | Index |

| Viscosity(mPa?s) | 30000±4500 |

| Square Resistance(Ω/□,25.4μm) | <0.5 |

| Electrothermal Conversion Efficiency | >98% |

| Heating Up Time(s) | <20 |

| Range of Infrared Radiation (μm) | 5-14 |

Intellectual Properties

One authorized patent(ZL201610330573.X).

Market Prospects

In China the current heating market situation is as follows: in 2011, 2012, and 2013 respectively realize such market sizes of 1.671, 1.911, and 2.100 billion RMB,and installation areas of 23100000 m2,27300000 m2,30000000 m2 respectively. State Grid Corporation of China has promoted and implemented 15 thousand clean electric heating projects, and installed electric heating area of about 500 million square meters by the end of 2017. China market for heating market is expected to grow at a compounded annual rate of 10% from 2018.

Technology Maturity

Laboratory research and development.

Cooperation

Cooperative development.

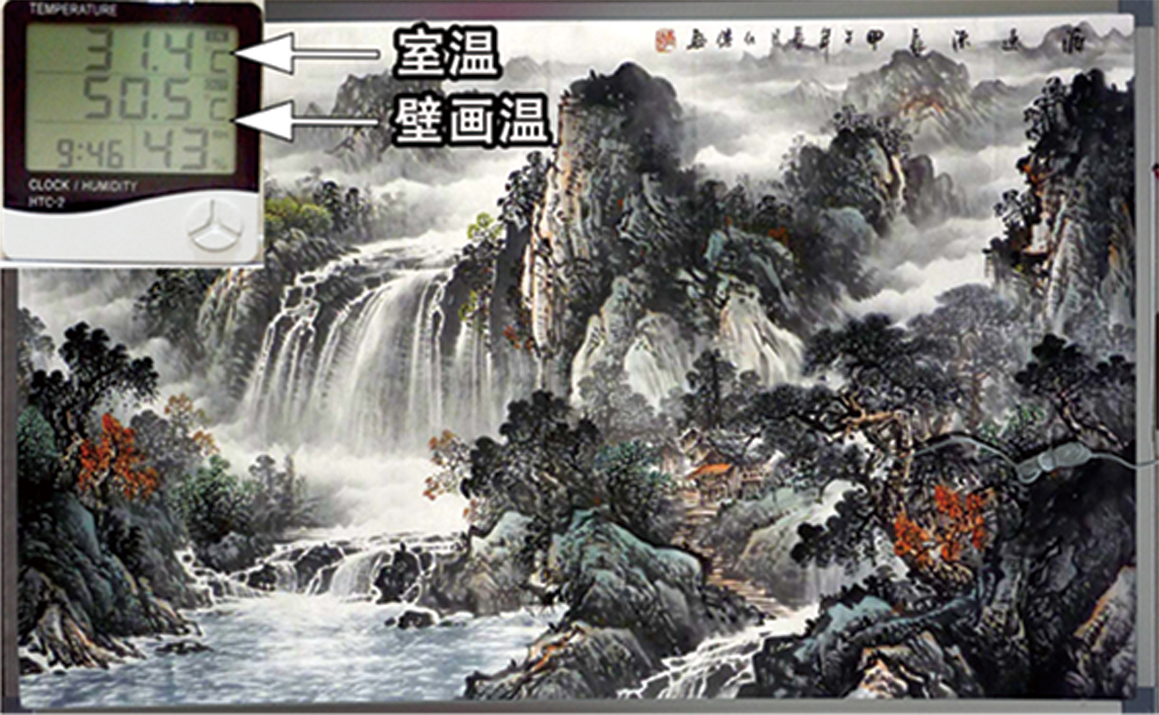

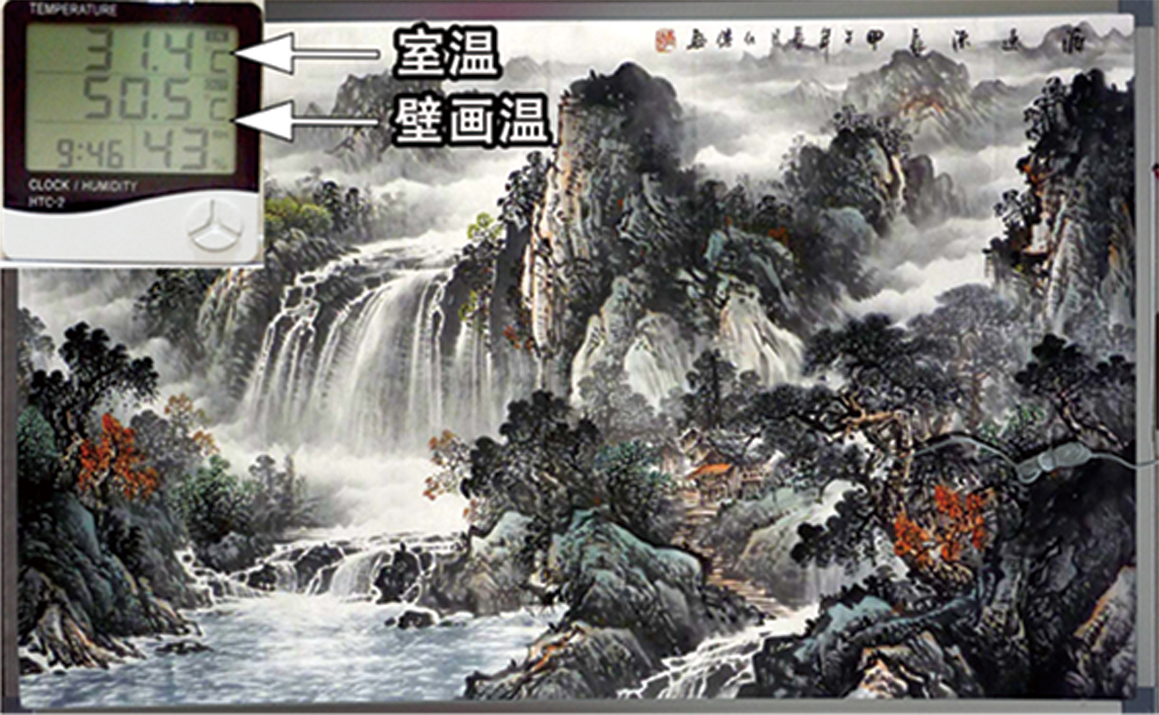

Graphene based infrared heating mural.

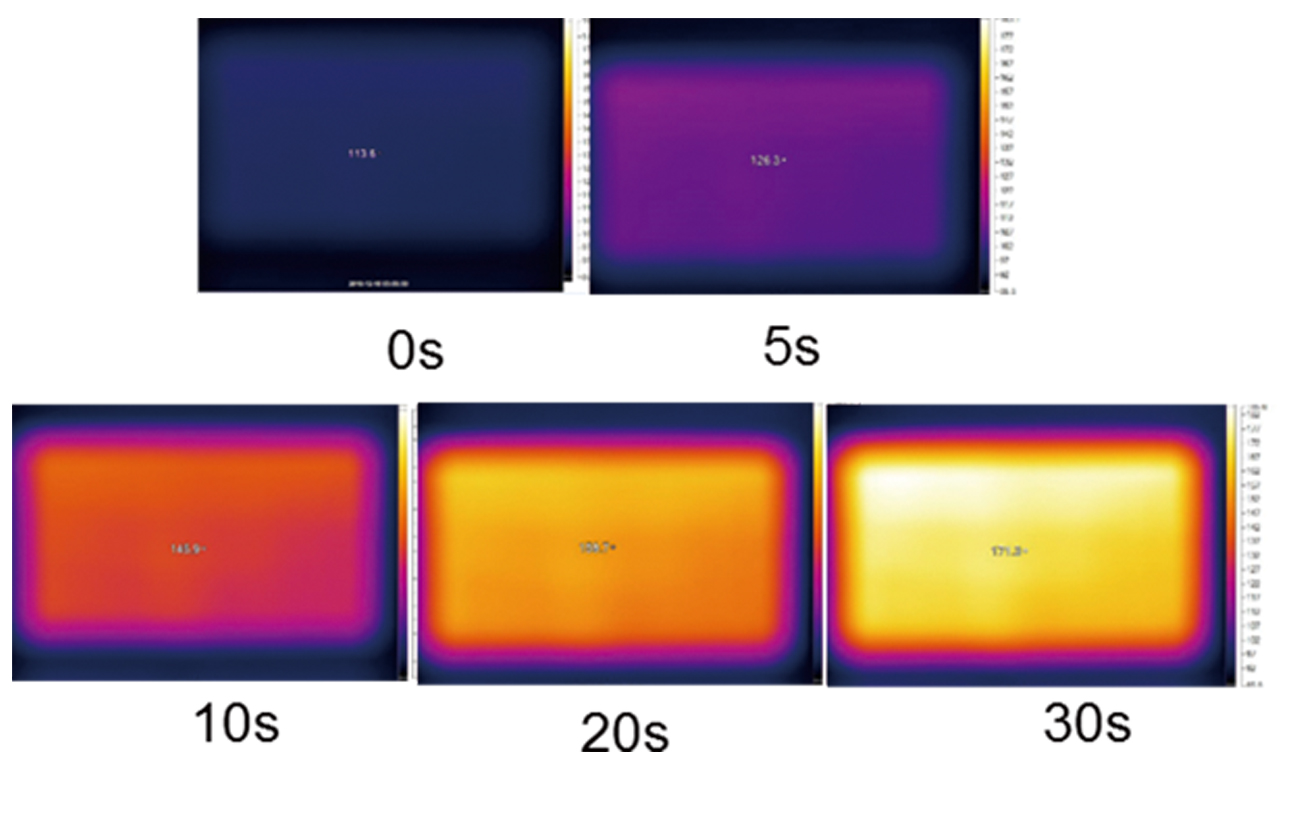

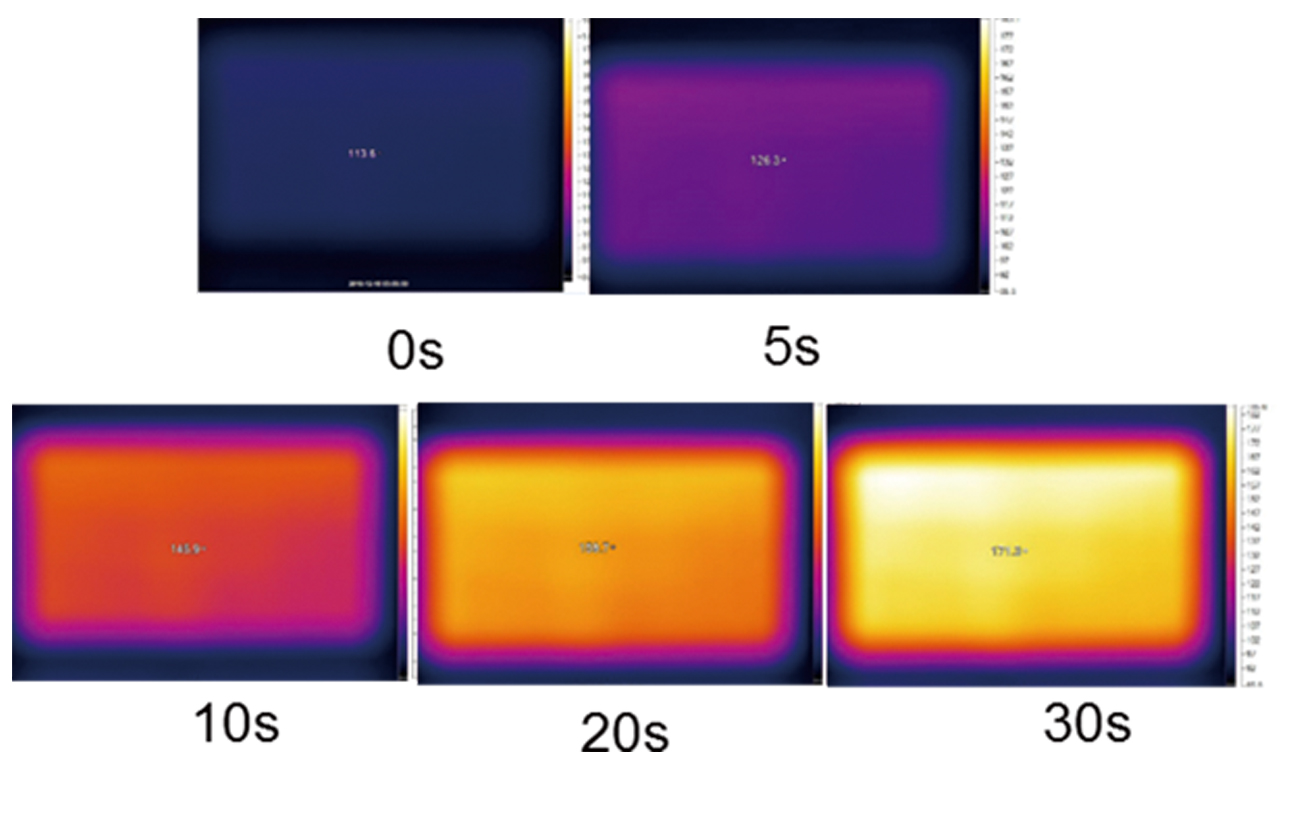

Heat radiation uniformity and heating time of the mural.

Infrared Heating Ink

Advantages

Graphene infrared heater can be made by simple coating or printing fabrication process with the advantage of energy-efficient. High aspect ratio and high conductivity of graphene provide the heater with strong infrared radiation, low drive voltage, high efficiency of electricity transforming and uniform heating. The infrared (5-14μm) heating system can not only be used for heating, but also for physical therapy on human bodies.

Technical Index

| Items | Index |

| Viscosity(mPa?s) | 30000±4500 |

| Square Resistance(Ω/□,25.4μm) | <0.5 |

| Electrothermal Conversion Efficiency | >98% |

| Heating Up Time(s) | <20 |

| Range of Infrared Radiation (μm) | 5-14 |

Intellectual Properties

One authorized patent(ZL201610330573.X).

Market Prospects

In China the current heating market situation is as follows: in 2011, 2012, and 2013 respectively realize such market sizes of 1.671, 1.911, and 2.100 billion RMB,and installation areas of 23100000 m2,27300000 m2,30000000 m2 respectively. State Grid Corporation of China has promoted and implemented 15 thousand clean electric heating projects, and installed electric heating area of about 500 million square meters by the end of 2017. China market for heating market is expected to grow at a compounded annual rate of 10% from 2018.

Technology Maturity

Laboratory research and development.

Cooperation

Cooperative development.

Graphene based infrared heating mural.

Heat radiation uniformity and heating time of the mural.

CONTACT US

Sales Manager:

0086+18835170493(Miss. Liu)

WeChat:18835170493

Technical support:

0086+13934640625(Miss. Guo)

graphene@sxicc.ac.cn

WeChat:13934640625

Tel/Fax:0086+03514049061

Post Code:030001

Adress:27 South Taoyuan Road, Taiyuan, Shanxi, P.R.China

Website:http://709.sxicc.ac.cn

0351-4049061