Graphene Modified Polymers

Technical Content

To obtain graphene modified polymer material with combined structural and functional integrated performance, graphene as nano functional filler is mixed with polymer matrix by physical of chemical methods. Liquid/solid dispersion and interface modifying are the key technology. The matched industrial technology and equipment for producing polymer composite in large scale have been also developed. The developed various types of polymer composites include graphene modified phenolic resin, graphene modified silicon rubber, and graphene modified polyethylene, etc. The other modified matrixes or functionalities can be developed according to requirements from customers.

Advantages

Graphene, as the key material in this project, is independently prepared by ICC-CAS, which has reached internationally advanced level. As a two-dimensional nano material, the uniform dispersion of graphene in polymer matrix is the precondition for obtaining the enhanced performances. This technology has designed the special dispersion process, which realizes the uniform dispersion and interface optimization of graphene in the matrix. Usability of graphene also becomes easy.

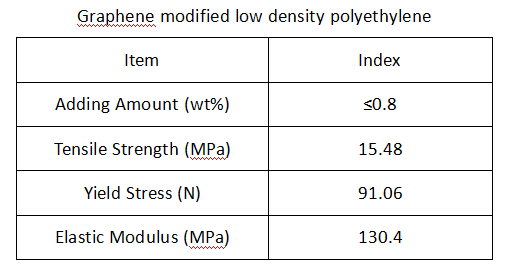

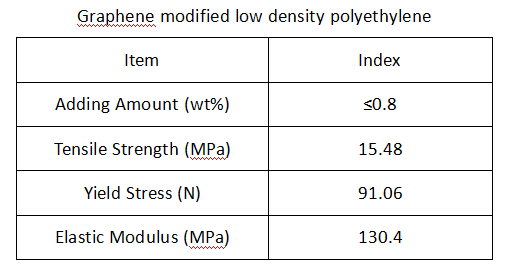

Technical Index

Intellectual Properties

One patent has been applied for(CN106117747A).

Market Prospects

There are great opportunities for the development of modified polymer in China. Taking modified plastics for example, the data show that China’s total plastic production rose from 18 million tons in 2004 to nearly 80 million tons in 2016. The ratio of modification has increased from 8% to 19%. However, compared to 40% of the modified plastics used in the global auto industry, China is only about 10%. The weight ratio of plastic to steel is an important parameter to measure the developmental level of plastic industry in a country. This value is only 30:70 in China, less than the international average of 50:50, and far less than the developed countries such as the America of 70:30 and Germany of 63:37. It becomes a critical stage for the quick development of modified polymer in China during the period of “the 13th five years plan”.

Technology Maturity

Laboratory research and development.

Cooperation

Cooperative development.

Super-hard grinding tools using graphene modified phenolic resin.

Graphene modified polyethylene.

Anisotropic silicon rubber modified by graphene

Graphene Modified Polymers

Technical Content

To obtain graphene modified polymer material with combined structural and functional integrated performance, graphene as nano functional filler is mixed with polymer matrix by physical of chemical methods. Liquid/solid dispersion and interface modifying are the key technology. The matched industrial technology and equipment for producing polymer composite in large scale have been also developed. The developed various types of polymer composites include graphene modified phenolic resin, graphene modified silicon rubber, and graphene modified polyethylene, etc. The other modified matrixes or functionalities can be developed according to requirements from customers.

Advantages

Graphene, as the key material in this project, is independently prepared by ICC-CAS, which has reached internationally advanced level. As a two-dimensional nano material, the uniform dispersion of graphene in polymer matrix is the precondition for obtaining the enhanced performances. This technology has designed the special dispersion process, which realizes the uniform dispersion and interface optimization of graphene in the matrix. Usability of graphene also becomes easy.

Technical Index

Intellectual Properties

One patent has been applied for(CN106117747A).

Market Prospects

There are great opportunities for the development of modified polymer in China. Taking modified plastics for example, the data show that China’s total plastic production rose from 18 million tons in 2004 to nearly 80 million tons in 2016. The ratio of modification has increased from 8% to 19%. However, compared to 40% of the modified plastics used in the global auto industry, China is only about 10%. The weight ratio of plastic to steel is an important parameter to measure the developmental level of plastic industry in a country. This value is only 30:70 in China, less than the international average of 50:50, and far less than the developed countries such as the America of 70:30 and Germany of 63:37. It becomes a critical stage for the quick development of modified polymer in China during the period of “the 13th five years plan”.

Technology Maturity

Laboratory research and development.

Cooperation

Cooperative development.

Super-hard grinding tools using graphene modified phenolic resin.

Graphene modified polyethylene.

Anisotropic silicon rubber modified by graphene

CONTACT US

Sales Manager:

0086+18835170493(Miss. Liu)

WeChat:18835170493

Technical support:

0086+13934640625(Miss. Guo)

graphene@sxicc.ac.cn

WeChat:13934640625

Tel/Fax:0086+03514049061

Post Code:030001

Adress:27 South Taoyuan Road, Taiyuan, Shanxi, P.R.China

Website:http://709.sxicc.ac.cn

0351-4049061