SiC Whiskers

Technical Content

This project introduces the reverse process of epitaxial growth of graphene from silicon carbide for the first time, using graphene as carbon resource and rice husk ash as silicon resource. SiC whisker in high quality is then obtained by carbothermic reduction. The industrialization preparation of graphene is realized with controlled cost. So it lays the foundation for preparing high value-added SiC whisker, taking advantage of the specific surface area and abundant edge. This project makes breakthrough for the functional application of graphene, and provides a new perspective for preparing carbide materials. This project shows wide prospect.

Advantages

As the two dimensional nano carbon resource, graphene plays important role in preparing high quality SiC whisker. This key material is produced by ICC-CAS using international advanced technique. The key parameters of graphene, including the content of functional groups, the lateral size, and the layers, can be customized produced during the practical preparation. So the optimal raw material is provided for the target whisker. This project provided way for the value-added application of rice husk, which is abandoned as waste. The whole project is completed without catalyst, and the reaction mechanism is easy. This project is liable to expanded production.

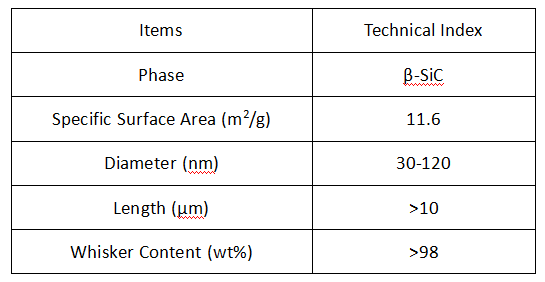

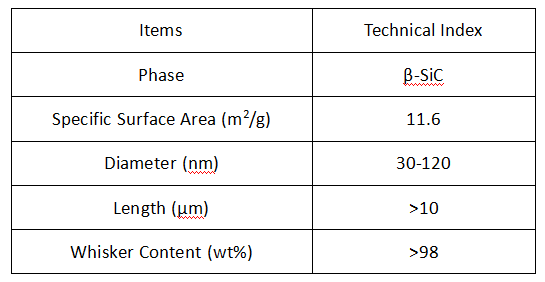

Technical Index

Intellectual Properties

One authorized patent(ZL201410110623.4).

Market Prospects

At present, the annual demand of SiC whisker is more than hundreds tons in worldwide. This material is monopolized by America with limited export. So the import amount is also limited in China. SiC whisker is in great demand in domestic market. Taking the ceramic blades used in machining industry as an example, the annual consumption is more than 2.5 million pieces in domestic market, among which the SiC whisker reinforced blades are all relied on import. If the single blade weighs 20 g and the content of SiC whisker is 15~20%, 3 g SiC whisker is required for every reinforced blade. So 7500 kg SiC whisker is in demand for 2.5 million pieces of blades. If considering the application in cutting, grinding and drilling tools, the domestic market of SiC whisker is large enough. The demand exceeds supply in the present market. Research by NASA shows that the success in surface coating technique will increase the requirement of SiC whisker. In a word, the investment risk in SiC whisker is low.

Technology Maturity

Laboratory research and development.

Cooperation

Cooperative development.

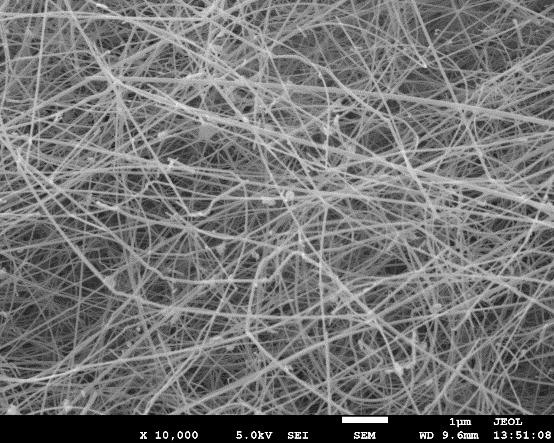

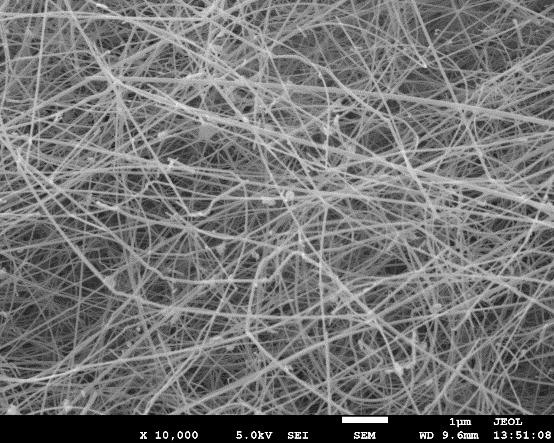

The SEM morphology of SiC whiskers.

The macrophotograph of SiC whiskers.

SiC Whiskers

Technical Content

This project introduces the reverse process of epitaxial growth of graphene from silicon carbide for the first time, using graphene as carbon resource and rice husk ash as silicon resource. SiC whisker in high quality is then obtained by carbothermic reduction. The industrialization preparation of graphene is realized with controlled cost. So it lays the foundation for preparing high value-added SiC whisker, taking advantage of the specific surface area and abundant edge. This project makes breakthrough for the functional application of graphene, and provides a new perspective for preparing carbide materials. This project shows wide prospect.

Advantages

As the two dimensional nano carbon resource, graphene plays important role in preparing high quality SiC whisker. This key material is produced by ICC-CAS using international advanced technique. The key parameters of graphene, including the content of functional groups, the lateral size, and the layers, can be customized produced during the practical preparation. So the optimal raw material is provided for the target whisker. This project provided way for the value-added application of rice husk, which is abandoned as waste. The whole project is completed without catalyst, and the reaction mechanism is easy. This project is liable to expanded production.

Technical Index

Intellectual Properties

One authorized patent(ZL201410110623.4).

Market Prospects

At present, the annual demand of SiC whisker is more than hundreds tons in worldwide. This material is monopolized by America with limited export. So the import amount is also limited in China. SiC whisker is in great demand in domestic market. Taking the ceramic blades used in machining industry as an example, the annual consumption is more than 2.5 million pieces in domestic market, among which the SiC whisker reinforced blades are all relied on import. If the single blade weighs 20 g and the content of SiC whisker is 15~20%, 3 g SiC whisker is required for every reinforced blade. So 7500 kg SiC whisker is in demand for 2.5 million pieces of blades. If considering the application in cutting, grinding and drilling tools, the domestic market of SiC whisker is large enough. The demand exceeds supply in the present market. Research by NASA shows that the success in surface coating technique will increase the requirement of SiC whisker. In a word, the investment risk in SiC whisker is low.

Technology Maturity

Laboratory research and development.

Cooperation

Cooperative development.

The SEM morphology of SiC whiskers.

The macrophotograph of SiC whiskers.

CONTACT US

Sales Manager:

0086+18835170493(Miss. Liu)

WeChat:18835170493

Technical support:

0086+13934640625(Miss. Guo)

graphene@sxicc.ac.cn

WeChat:13934640625

Tel/Fax:0086+03514049061

Post Code:030001

Adress:27 South Taoyuan Road, Taiyuan, Shanxi, P.R.China

Website:http://709.sxicc.ac.cn

0351-4049061