Activated Carbon for Supercapacitor

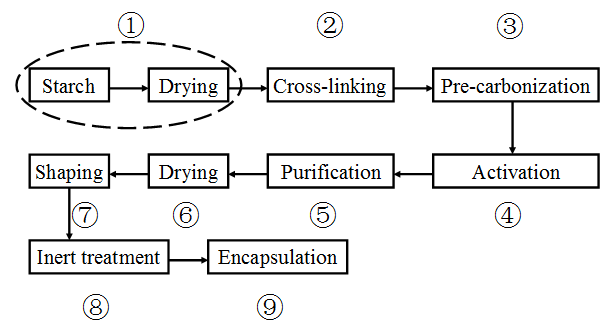

Using starch as precursor, activated carbon for supercapacitor is prepared through 9 steps. Among which, crosslinking, catalytic activation at high temperature and totally purification are the three key technologies.

Advantages

Three advantages of this technology: (1) using starch as raw material, so the morphology and physicochemical parameters are easy to control; (2) advanced technology is employed in crosslinking, carbonization and activation, which ensures the stability of quality for the different batch products; (3) the waste gas and liquid are dealt with further post processing without pollutant.

Technical Index

Physical Parameter

| Morphology | Spherical |

| SBET (m2/g) | 1750 |

| <3 | |

| Average Particle Size (D50 μm) | 11 |

| Bulk Density (g/ml) | 0.41 |

| Ash Content (wt%) | 0.04 |

| Fe Ions Content (ppm) | 15 |

| Oxygen Content (wt%) | 1.25 |

Electrochemical Parameter

| Model | 22450 cylinder |

| Activated Carbon Content (wt%) | 85 |

| Conductivity Agent (wt%) | 8 |

| CMC (wt%) | 2 |

| Binder (wt%) | 5 |

| Electrolyte | CF4301 |

| Slurry Viscosity (mPa s) | 5577 |

| Solid Content (wt%) | 24.9 |

| Coating Scraper (μm) | 300 |

| Areal Density (g/2.5434 cm2) | 0.033 |

| Compacted Density (g/ml) | 0.57 |

| Injection Volume (g) | 7.7 |

| Device Mass (g) | 21.6 |

| R203 (mΩ) | 7 |

| Charge Capacity (F) | 145.3 |

| Discharge Capacity (F) | 143.5 |

| Leakage Current (mA, 2h) | 7.7 |

| DCIR (mΩ) | 9.0 |

| Specific Capacitance (F/g) | 153.4 |

| Specific capacitance (F/cc) | 20.7 |

| Energy Density (Wh/kg) | 6.73 |

| Power Density (Wh/kg) | 9.38 |

Intellectual Properties

Two authorized patents(ZL201510062117.7, ZL201510062450.8).

Preliminary Application

This technology has been applied in supercapacitors.

Economic Evaluation

The requirement of supercapacitor in China will reach to 21.5 million, about 120 million Wh. If the energy density of activated carbon for supercapacitor is 5 Wh/kg, 10,000 tons per year of activated carbon will be needed, which brings 6-8 billion RMB output value.

Technology Maturity

Pilot amplification.

Cooperation

Cooperative development.

Activated carbon for supercapacitor.

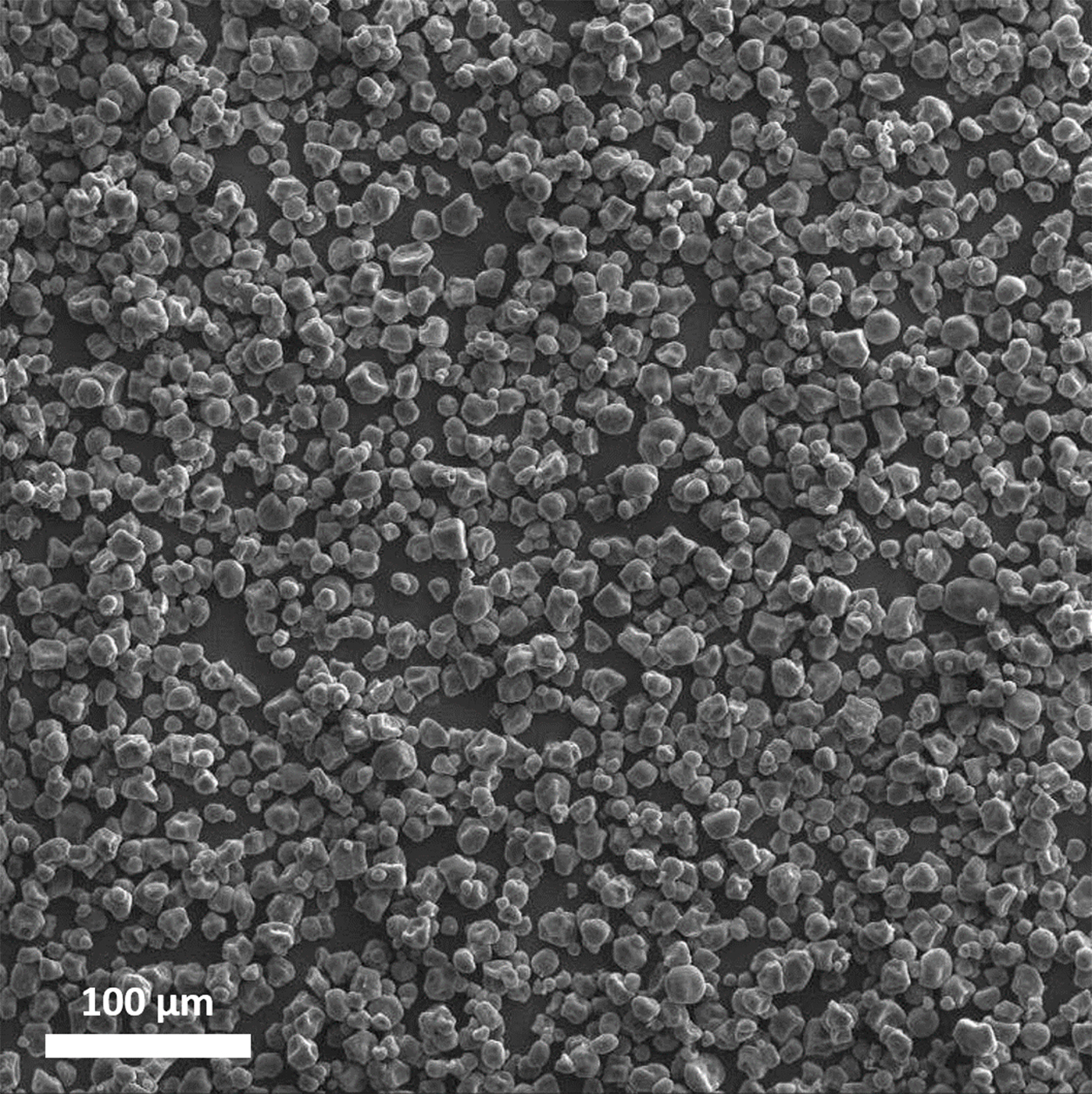

The microscopic morphologies of activated carbon for supercapacitor.

The pilot platform of activated carbon for supercapacitor.

Activated Carbon for Supercapacitor

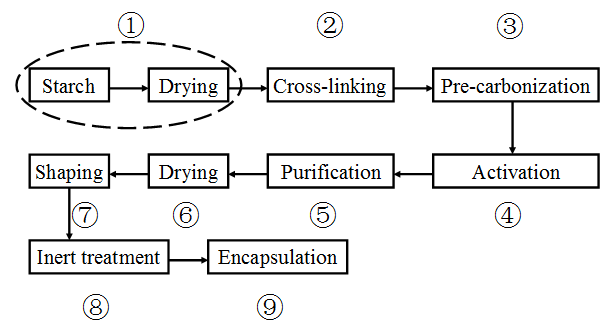

Using starch as precursor, activated carbon for supercapacitor is prepared through 9 steps. Among which, crosslinking, catalytic activation at high temperature and totally purification are the three key technologies.

Advantages

Three advantages of this technology: (1) using starch as raw material, so the morphology and physicochemical parameters are easy to control; (2) advanced technology is employed in crosslinking, carbonization and activation, which ensures the stability of quality for the different batch products; (3) the waste gas and liquid are dealt with further post processing without pollutant.

Technical Index

Physical Parameter

| Morphology | Spherical |

| SBET (m2/g) | 1750 |

| <3 | |

| Average Particle Size (D50 μm) | 11 |

| Bulk Density (g/ml) | 0.41 |

| Ash Content (wt%) | 0.04 |

| Fe Ions Content (ppm) | 15 |

| Oxygen Content (wt%) | 1.25 |

Electrochemical Parameter

| Model | 22450 cylinder |

| Activated Carbon Content (wt%) | 85 |

| Conductivity Agent (wt%) | 8 |

| CMC (wt%) | 2 |

| Binder (wt%) | 5 |

| Electrolyte | CF4301 |

| Slurry Viscosity (mPa s) | 5577 |

| Solid Content (wt%) | 24.9 |

| Coating Scraper (μm) | 300 |

| Areal Density (g/2.5434 cm2) | 0.033 |

| Compacted Density (g/ml) | 0.57 |

| Injection Volume (g) | 7.7 |

| Device Mass (g) | 21.6 |

| R203 (mΩ) | 7 |

| Charge Capacity (F) | 145.3 |

| Discharge Capacity (F) | 143.5 |

| Leakage Current (mA, 2h) | 7.7 |

| DCIR (mΩ) | 9.0 |

| Specific Capacitance (F/g) | 153.4 |

| Specific capacitance (F/cc) | 20.7 |

| Energy Density (Wh/kg) | 6.73 |

| Power Density (Wh/kg) | 9.38 |

Intellectual Properties

Two authorized patents(ZL201510062117.7, ZL201510062450.8).

Preliminary Application

This technology has been applied in supercapacitors.

Economic Evaluation

The requirement of supercapacitor in China will reach to 21.5 million, about 120 million Wh. If the energy density of activated carbon for supercapacitor is 5 Wh/kg, 10,000 tons per year of activated carbon will be needed, which brings 6-8 billion RMB output value.

Technology Maturity

Pilot amplification.

Cooperation

Cooperative development.

Activated carbon for supercapacitor.

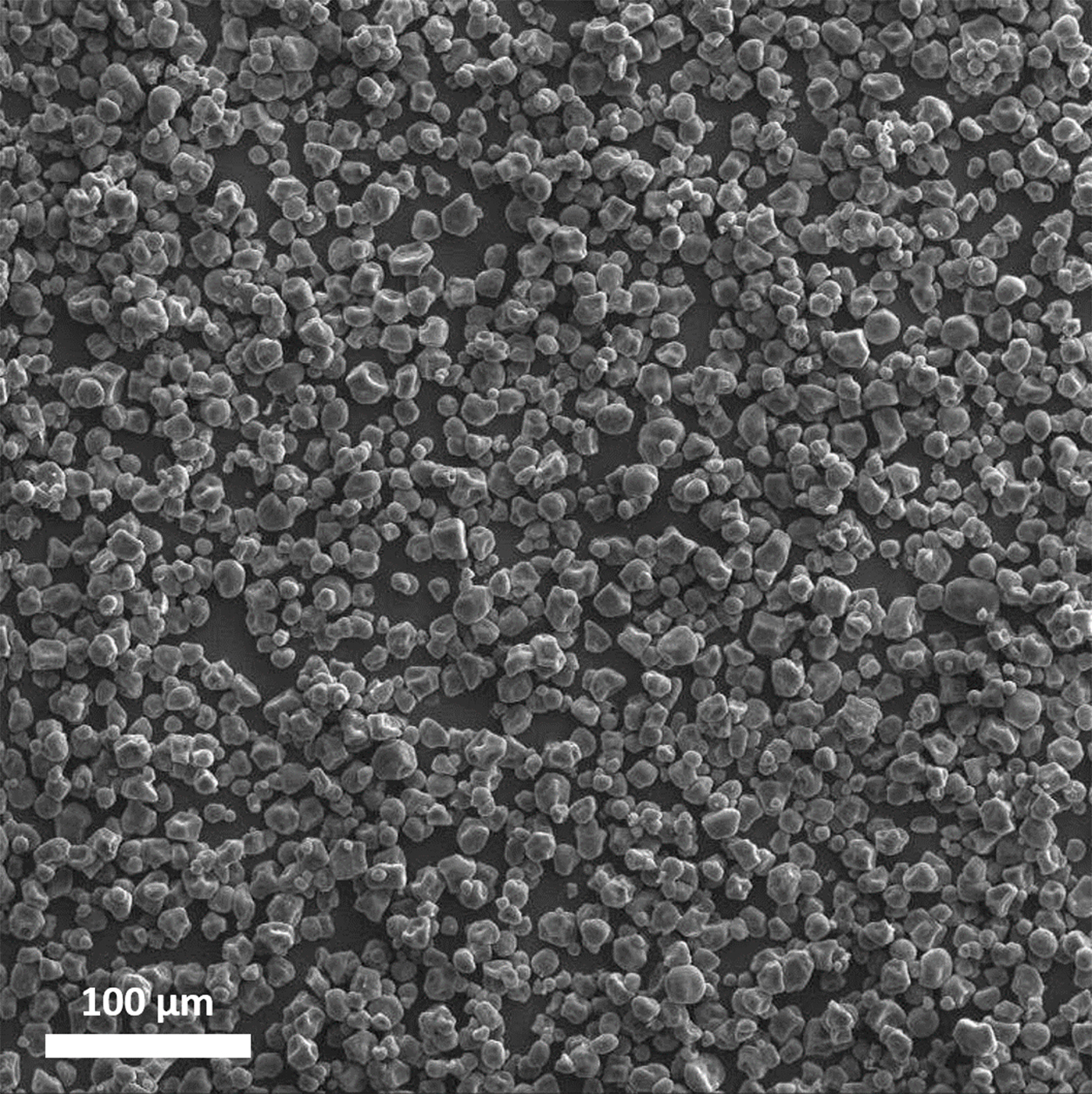

The microscopic morphologies of activated carbon for supercapacitor.

The pilot platform of activated carbon for supercapacitor.

CONTACT US

Sales Manager:

0086+18835170493(Miss. Liu)

WeChat:18835170493

Technical support:

0086+13934640625(Miss. Guo)

graphene@sxicc.ac.cn

WeChat:13934640625

Tel/Fax:0086+03514049061

Post Code:030001

Adress:27 South Taoyuan Road, Taiyuan, Shanxi, P.R.China

Website:http://709.sxicc.ac.cn

0351-4049061